Scroll

貴社のビジネスに適切なサービスをご提案し、ロボティクス、オートメーション、デザインで「成果」に貢献いたします。

製品とサービス

株式会社埼玉富士の主な製品とサービスについて。工場の省力化&ロボット化サービス、業務の自動化&デジタル化サービス、大物金属部品の精密加工サービス、制御機器の受託組立サービスの紹介。

モノづくり環境は、グローバル化により大きく変化しました。デジタル技術革新に伴い、モノづくりの手法も多様化が進み、必要な技術も変化しています。

地球環境や品質確保に適した技法や素材を慎重に選択し「ワンストップ&エンジニアリング」でお客様の課題を解決する最適な製品やサービスをご提案させて頂きます。

工場の省力化&ロボット化

生産工程の省力化&ロボット化(Factory Automation)サービス。高速組立&安定品質のニーズに対応する専用装置(ハードウェア&ソフトウェア)を設計・製作・納入・設置します。

業務の自動化&デジタル化

アナログ業務の自動化&デジタル化(Digital Transformation)サービス。見える化&省人化&IoT化のニーズに対応する専用システム(ハードウェア&ソフトウェア)を開発・設計・製作します。

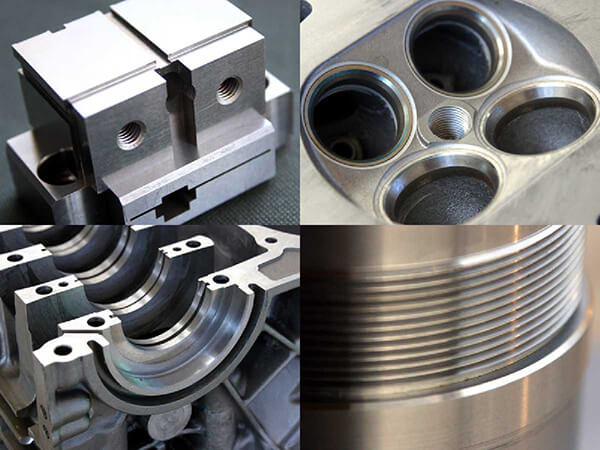

金属部品の機械加工

大物ワーク(長物1700mm、丸物1250mm)の試作や小ロット品の加工サービス。多様な材質対応、特殊工具の保有、CAD/CAMの連携、品質管理体制を、ワンストップで提供。

制御機器の受託組立

制御機器や電子機器の受託組立サービス。富士電機㈱様の協力工場として50年以上培った製造技術力(半田・樹脂成形・巻線・組立)でモノづくりを提供致します。

採用情報

モノづくりに興味があり、よりよい社会の実現に興味がある方。是非、私たちと一緒に活動しませんか? 社会が求める「モノづくりサービス」を考えて創造したいエンジニアを募集しています。 当社では多業種&多品種のエンジニアにより、様々な経験を積むことができます。

エンジニアとして成長して頂く為の会社の制度として、教育制度にも力を入れております。 階層別教育体系の実施や専門別教育など育成支援を行っています。 又、取得奨励資格については、受験料補助や取得奨励金も支給しています。

更に、近年は福利厚生として「次世代育成支援」にも力を入れています。 従業員が長期に安心して働ける様、子育てや介護の支援等、仕事と生活の両立を図りやすい雇用環境の整備を進めています。

新卒者の採用

当社では、新しいモノを作ることに「楽しさ」「やりがい」を感じる「未来のエンジニア」を募集しています。 自然豊かな当社で一緒に活動し、より豊かな社会の実現に貢献してみませんか?

新卒者の採用詳細

中途者の採用

当社では、今までにないモノやサービスを「創り出す」ことに誇りを持つ「現役のエンジニア」を募集しています。 「自分の技術や経験を新たな場で発揮したい」と思っている貴方。当社のエンジニアとして一緒に働きませんか?

中途者の採用詳細企業情報

保有設備

株式会社埼玉富士が保有する設備について。複合加工機、マシニングセンタ、旋盤、フライス盤、放電加工機、研削盤、プレス・モールド、精密板金、プリント基板実装、微細加工、測定機器等。

保有設備一覧について